Quarantine Projects

When the COVID-19 pandemic hit the summer of 2020 became a summer of indoor engineering projects. I decided to spend my newfound free time exploring my 3D printer by printing springs, bearings, and a toy gun. I also spent time building a map for EasternSeals and coding an Android app to have my phone scream whenever it fell.

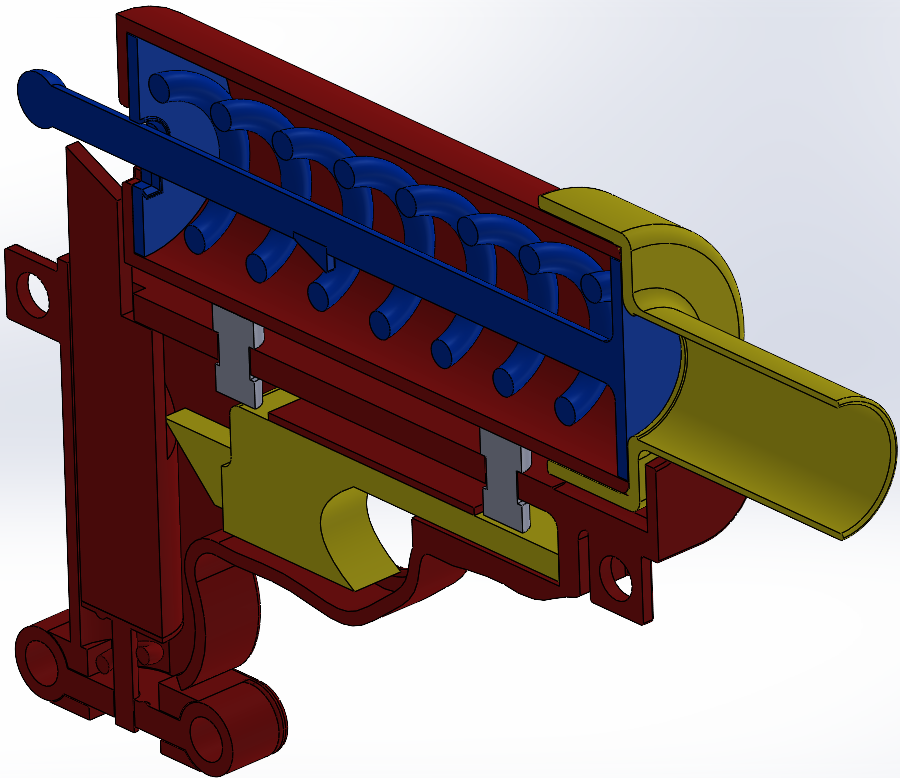

A cross-sectional view of my 3D printed toy gun.

3D Printed Toy Blaster

I started my summer off printing springs. I was curious if my red PLA was flexible enough to act like an ideal spring. It turns out, that the PLA was very flexible and I could print springs in all sorts of sizes. I was able to print extremely long springs using supports. I also used threads to combine springs together using male-to-female connectors. With this design, I could make long springs for all sorts of wacky projects. For example, I improved my assembly modeling skills by designing a gun that only used 3D-printed parts.

A lineup of several 3D printed spring iterations.

After studying how Nerf guns use air to accelerate their bullets, I decided to encase my springs to make my own toy gun. I then designed a two-part handle that would connect together using 3D-printed screws and bolts. Inside the handle, I included a locking mechanism such that I could store energy in the spring and release it by disengaging the lock through the trigger. The project took several iterations and many hours of printing to complete. But once I did, I had a small toy gun that could shoot a small foam ball about four feet away.

A clip of me firing my 3D printed toy gun.

3D Printed Toy Blaster V2

After the success of the first gun, I wanted to see if a longer spring could store more energy and thus launch the bullet further. So I daisy-chained springs together and created a cartoonishly long toy gun. I couldn’t have a solid plastic shaft running down the length of the gun, so I hooked some string and wound it around a cranking wheel. I could then use the same mechanism from the smaller gun, and progressively load the springs by hand. Although my design was functional, it actually shot the ball a shorter distance than the original. This is probably because the energy loss due to friction throughout the length of the barrel was enough to negate any gained energy over the original gun.

A model of the long version of the toy gun.

Another project I did was trying to 3D print a moving bearing with one print. Initially, I tried using the default settings on my printer to print spheres encased in two rings. But once I finished printing it, the spheres melted into the plastic of the rings, and the bearing couldn’t spin. So, I attempted to add 0.2mm of room between the balls and the rings, but then the ball bearings kept falling out. After several iterations, I ran into versions where parts spun, but would rub against the balls instead of rolling. I then looked online and noticed someone used a slower print speed and a smaller nozzle diameter to print their bearings. So, I set the print speed to 30 mm/s and made my printer’s nozzle diameter 0.2mm. This made print times longer, but I was able to reduce the clearance between the balls and the casing. After a few more iterations, I was able to find a balance between support, clearance, and encasing to have a bearing that could spin quickly and retain its structure.

A line up of my bearing iterations.

Single Print Ball Bearings

Raised Map for Easter Seals

A close up of the EasternSeals office map

A photo of me and the point of contact from EasternSeals (IIRC this was about a year before the pandemic so no masks).

Just before the pandemic, I worked with my high school to develop some assistive technology products. One of the challenges I took on was designing a map for the EasternSeals office in Worcester, MA. EasternSeals is a non-profit focused on assisting the disabled. They needed a map of their facilities that could help the visually impaired. I worked with one of the teachers who runs my high school’s printers and printed nine puzzle pieces that could fit together to form one large map. The map had raised walls and titles for people to feel. I used super glue to fit the nine pieces together and a brushed bit on a Dremel to melt the plastic around the edges of each piece. Although the map was fragile, it was functional and I was told benefitted the EasterSeals office.

Making my Phone Feel Pain

A final project during quarantine was an Android app that would make my phone scream whenever it fell. I used Android Studio and Java to code an app that would access my phone’s accelerometer data and play one of four audio files if the acceleration passed a threshold. I also enabled a toggle switch so the phone would not scream if one was, for example, running.

A demo video of the phone screaming app.